- +91-9886121000

- pureflowbiofloc@gmail.com

- Equipment Catalog

Pureflow biofloc innovations

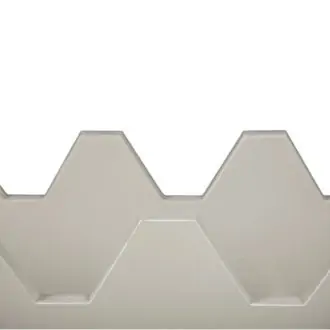

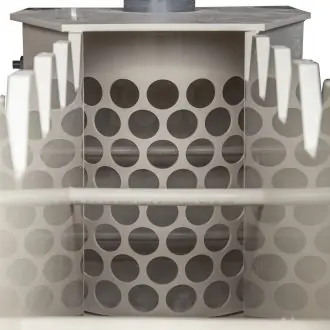

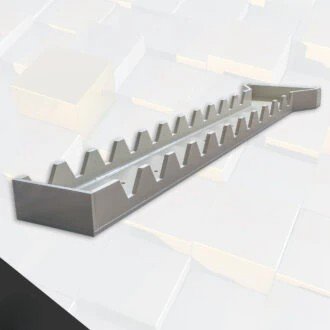

Overflow Launders

Aquaculture Overflow Launders

The Overflow Effluent Launder is a robust structural element built of PP (Polypropylene) and it allows the water to trickle and degas through its gradual flow design. It is used in industrial effluent wastewater treatment and in intensive land based fish farming applications as a degassing / aeration solution.Manufactures custom overflow effluent launders according to each fish farm design specifications.

Overflow Launders - SPECIFICATIONS

- Overflow Launder Search:

You are trying to load a table of an unknown type. Probably you did not activate the addon which is required to use this table type.

Preserves the right to update anytime the listed prices (if any). Every effort has been made so that the above specs are accurate. However please contact our Sales Department for up to date technical data, electrical specs according to your regional requirements and current Ex-Works pricelist. The listed prices are for the basic equipment and do not include any optional components.

REQUEST A QUOTE