- +91-9886121000

- pureflowbiofloc@gmail.com

- Equipment Catalog

Pureflow biofloc innovations

Dissolved Air Flotation Systems (DAF)

Dissolved Air Flotation

The Dissolved Air Flotation (DAF) by MAT-KULING is a superior physical/chemical technology designed to treat a variety of industrial and municipal processes and wastewater streams. DAF systems are widely implemented to achieve multiple treatment objectives such as:

- Plant Discharge Wastewater Treatment and Recovery

- Food Packing, Processing Plant Discharge Water Treatment

- Land-Based Aquaculture Discharge Water Treatment

- Pretreatment for sewer discharge compliance

- Reduction of loading on downstream biological systems

- Polishing of biological treatment effluent

- Biosolids thickening

MAT-KULING has the technology and expertise to fabricate safe ozone generators that deliver the actual ozone specified output. The Ozone generators are fabricated for ozone infusion into the water. A solution for an effective, safe and natural disinfection process. Ozone gas is oxidant and dangerous and should be produced and handled under strict monitored operation practices.

Our devices are applicable to Recirculated Aquaculture Systems and other water treatment facilities.

Advantages of DAF

- Pre-Assembled, Skid-Mounted Configuration – Delivers a ready-toinstall setup, minimizing the need for on-site assembly.

- Efficient Rectangular Design: – Maximizes space utilization with its compact rectangular shape.

- High-Quality Drive and Pump Components: -Ensures long-term dependability with premium quality components.

- Customization Options Available with Minimal Effect on Delivery Timelines or Costs

- Non-Corrosive Tank Construction from PP & PE: Engineered for durability – The tank is designed to resist flexing under operational stress. – Available in also 304, 316, and 316L Stainless Steel tank constructions.

- Space-Efficient Design with Integrated Plate Pack: – Ideal for spaceconstrained environments, offering compact and efficient use of space.

- Uniform High-Quality Production and Advanced Manufacturing: -Ensures consistent and superior product quality, leveraging cutting-edge production technology.

- Streamlined Flow for Enhanced Separation Efficiency: – Improves the effectiveness of the separation process, leading to better contaminant removal.

DAF Standard Features

- DAF is made of a non-corrosive tank,

- Skimmer

- settling structure

- sludge/water connections,

- air supply, pneumatic panel, and air supply valve

- recirculation pump.

- Lamella Plate Pack (only DAF-L models)

Dissolved Air Flotation

- DAF Optional Features

- Coagulant dosing pump.

- Caustic soda dosing pump.

- Flocculant (polyelectrolyte) preparation and dosing system.

- pH sensor

- Dosing Line Flowmeters

- Sludge Pump

- Sludge Screw Extractor

- Flotation Tank Level Sensor

- Process Flow Monitoring Sensor

- Sludge Level Measurement

- TSS (Total Suspended Solids) Monitoring in Inlet and Outlet

- Smart Control Panel with Relay Logic and Microcontroller

- PLC/HMI for operational flexibility

- Access Platforms and Staircases

- Flotation Tank Cover/Lid.

- Incorporated Skid-Mounted Flocculation Tubing: In-line flocculator —with Floculant, Coagulant, Costing dosing points, sampling and pH sensor taps.

Components of a DAF System

-

Flotation

Tank -

Automated scraper/skimmer

-

Recirculation

pump -

Pressurized white water unit

-

Pressure

Tank -

Sludge

Flotation Tank

The Flotation Tank is the main vessel where the actual separation process occurs. The pressurized white water is released into the flotation tank. The sudden reduction in pressure releases the dissolved air in the form of tiny bubbles which motivate particles in the wastewater will ascend to the surface. The Flotation tank is made of fully non-corrosive thermoplastic material and optionally from steel. The Tank provides surface area for the flotation of air and flocculated particles (float).

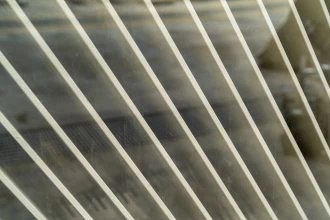

However, MAT-KULING DAF units employ the use of inclined lamella plates in the flotation tank optionally to augment the separation of solids.

Automated scraper/skimmer

An automated scraper/skimmer mechanism continually removes these floating particles. As the bubbles rise, they carry the suspended particles with them to the surface, forming a froth/foam layer. A skimmer mechanism is used to remove this sludge from the surface of the water. The surface skimmer is designed for the efficient removal of floating materials from the surface of the flotation cell. This system commonly employs a chain of flights, driven by a variable-speed, timer-operated mechanism. As an optional addition, a bottom skimmer or auger can be incorporated for the removal of settled solids from the bottom of the flotation unit.

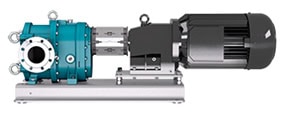

Recirculation pump

MAT-KULING DAF systems include a recirculation pump to recycle a portion of the treatment flow (20-30%) back into the DAF system. This helps to maintain a constant flow and pressure in the system, enhancing efficiency and providing water for the pressurized white-water system.

Pressurized white water unit

The pressurized white-water unit provides recirculation and aeration. This set of devices includes a recirculation pump, an air compressor(externally), and a pressurized tank to generate air bubbles that aid in the separation of particles within the wastewater. The implementation of a pressurized white-water unit, generating bubbles ranging from 35 to 65 microns, significantly boosts separation efficiency. The rationale behind this is straightforward: smaller bubbles have a greater surface area relative to their volume, allowing for more effective adherence to particles, and thereby enhancing the overall efficacy of the flotation system.

Pressure Tank (Contact Chamber)

Pressure Tank (Contact Chamber) is where the pressurized water and air are mixed. The high pressure in the tank dissolves the air into the water and generates white water. The air compressor (external) is used to introduce air into the water under high pressure. This is a critical component as the size and quantity of the air bubbles formed significantly affect the efficiency of the flotation process.

The sludge pump or Sludge Screw Extractor

The sludge pump or Sludge Screw Extractor in a DAF system is vital for the efficient operation of the process, enabling the continuous removal of contaminants, preventing system disruptions, and facilitating the further handling of the removed sludge. Additionally, the system may be fitted with automatic valves designed for the expulsion of any sediment that settles at the bottom.

-

Lamella plate pack

-

Flocculators

-

Coagulants

-

Polyelectrolyte preparation

-

Coagulant & Caustic Dosing

-

Controller Unit

Lamella plate pack

The system incorporates a lamella plate pack, which expands the unit's separation surface, ensuring the removal of even minuscule flocs, thereby enhancing the compactness of the unit.

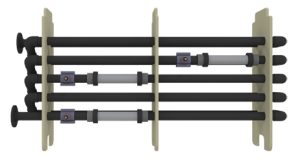

Flocculators

Flocculators introduce chemicals into water to enhance the flotation process. The Pipe Flocculator follows the in-line process, combining coagulation, flocculation, and pH adjustment in a controlled environment. Its design ensures uniform retention time and consistent mixing energy, leading to the formation of uniform flocs with excellent separation properties.

Coagulants

Coagulants are chemicals added to the water to cause destabilization of colloidal particles. They neutralize the electrical charges of particles in the water, which obstructs their ability to repel each other. This action allows the particles to come closer together, forming larger particles (microflocs). Common coagulants include aluminum sulfate, ferric chloride, and PAC (Polyaluminum chloride). After coagulation flocculants are added to gather the microflocs into larger flocs. These are larger, more complex molecules that facilitate the binding together of the destabilized particles. Flocculants are essentially long-chain polymers that increase the size of the flocs, making them heavier and easier to remove through the flotation process in the DAF system.

The efficiency of clarification hinges on the accurate selection and dosing of coagulants, flocculants, and pH adjusting agents, coupled with precise process control. With proper application, chemical precipitation can eliminate up to 90% of suspended solids, reduce BOD5 by up to 80%, and remove 90% of bacteria.

Polyelectrolyte preparation system

In Dissolved Air Flotation (DAF) systems, a polyelectrolyte preparation system is typically used for preparing and dosing flocculants. Polyelectrolytes, which are long-chain polymer compounds, act as flocculants. They are effective in binding the smaller floc particles formed by coagulants into larger, more settleable, or floatable aggregates.

The preparation system for polyelectrolytes usually involves mixing the polymer (which can be in liquid or powder form) with water to achieve the desired concentration, followed by maturation and dosing. This process ensures that the flocculant is evenly distributed and fully functional when introduced into the DAF system.

In contrast, coagulants, which are typically simple, inorganic salts like aluminum sulfate or ferric chloride, don't require such extensive preparation and are often dosed directly in their original form from their holding tank. The polyelectrolyte preparation system typically involves the mixing of a dry polyelectrolyte powder or liquid concentrate with water to create a solution. This process is usually carried out in a batch mode in a dedicated tank. The system consists of facilities for storage, metering, and mixing polyelectrolytes with water.

Coagulant Dosage pumps and Caustic Dosing pumps

Coagulant Dosage pumps inject coagulants (like aluminum or iron salts) into the water. The coagulants neutralize the electrical charges of particles in the water, causing them to clump together, making them easier to remove.

Caustic dosing pumps add substances like sodium hydroxide to the water. This adjusts the pH level, optimizing conditions for coagulation and flocculation processes.

Proper dosing by these pumps ensures efficient removal of suspended particles and colloids, leading to clearer, cleaner water post-treatment. These pumps can be automated for precise control of chemical dosages, ensuring consistent water treatment quality while minimizing chemical usage and cost.

Controller Unit

The Controller Unit is essential for monitoring and controlling the DAF process. It ensures the proper balance of air pressure, water flow, and skimming rate to optimize the flotation process for different types of waste.

Dissolved Air Flotation Systems (DAF) - SPECIFICATIONS

- Dissolved Air Flotation Systems (DAF)

- DAF-L (Lamella Plate)

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | MODEL | DAF-5 | DAF-10 | DAF-20 | DAF-35 | DAF-50 | DAF-100 | DAF-150 | DAF-200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 47 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Annual Hydraulic Capacity [m3/h] | 5 | 10 | 20 | 35 | 50 | 100 | 150 | 200 |

| 48 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Annual Hydraulic Loading Rate[m/h] | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| 49 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Free Flotation Area[m2] | 1.25 | 2.5 | 5 | 8.8 | 12.5 | 25 | 38 | 50 |

| 50 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Lamella Surface Area[m2] | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| 51 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Solid Loading Rate Range[kg/h/m2] | 25-45 | 25-45 | 25-45 | 25-45 | 25-45 | 25-45 | 25-45 | 25-45 |

| 52 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | A/S – Air-Solid Ratio Range[kg/kg] | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 |

| 53 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flotation Tank Length[mm] | 2500 | 3150 | 5000 | 7000 | 8000 | 9500 | 14000 | 17000 |

| 54 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flotation Tank Height[mm] | 1400 | 1500 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| 55 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flotation Tank Width[mm] | 1900 | 2000 | 2400 | 2300 | 2400 | 3400 | 3400 | 3400 |

| 56 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Empty Flotation Tank Weight[kg] | 520 | 1250 | 2200 | 2500 | 2800 | 4700 | 5400 | 6400 |

| 57 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Full Flotation Tank Weight[kg] | 1600 | 3300 | 11500 | 14000 | 17000 | 29500 | 42000 | 53800 |

| 58 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flotation Tank Material- | PP | PP | PP | PP | PP | PP | PP | PP |

| 59 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Skimmer Motor Power[kW] | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 |

| 60 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Recirculation Pump Annual Flow[m3/h] | 1.25 | 2.5 | 5 | 8.75 | 12.5 | 25 | 37.5 | 50 |

| 61 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Recirculation Water Annual Pressure[Bar] | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 |

| 62 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Recirculation Pump Motor Power[kW] | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 15 | 15 | 15 |

| 63 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Pressurized Tank Volume[l] | 62.5 | 125 | 250 | 437.5 | 625 | 1250 | 1875 | 2500 |

| 64 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Annual Pressurized Tank Contact Time[min.] | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 65 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Required Compressed Air Pressure[Bar] | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 |

| 66 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Required Normal Air Flow[Nm3/h] | 11 | 21 | 42 | 73 | 104 | 208 | 312 | 416 |

| 67 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Inlet Connection[DN] | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| 68 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Effluent Connection[DN] | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| 69 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Float Discharge Connection[DN] | 80 | 80 | 80 | 100 | 100 | 125 | 150 | 200 |

| 70 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Settled Solid Discharge Connection[DN] | 50 | 50 | 50 | 65 | 80 | 100 | 125 | 150 |

| 71 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Pressurized Air Connection[inch] | 1/2″ | 1/2″ | 3/4″ | 3/4″ | 1″ | 1 1/2″ | 2″ | 2 1/2″ |

| 72 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Sludge Screw Power[kW] | N/A | N/A | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 |

| 73 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Sludge Pump Power[kW] | 0.5 | 0.5 | N/A | N/A | N/A | N/A | N/A | N/A |

| 74 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Inline Flocculator Model- | IPF-5 | IPF-10 | IPF-20 | IPF-35 | IPF-50 | IPF-100 | IPF-150 | IPF-200 |

| 75 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Standard Flocculator Tube Material – | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE | U-PVC/PP/PE |

| 76 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flocculator Tube Diameter [DN] | 63 | 75 | 90 | 110 | 110 | 160 | 200 | 200 |

| 77 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flocculator Total Tube Length [m] | 20 | 30 | 40 | 45 | 62 | 62 | 62 | 80 |

| 78 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Coagulant Dosage Pump Capacity[l/h] | 5 | 10 | 20 | 35 | 50 | 100 | 150 | 200 |

| 79 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Coagulant Tank Model- | CDS-500 | CDS-500 | CDS-1000 | CDS-1000 | CDS-2000 | CDS-2000 | CDS-3000 | CDS-4000 |

| 80 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Coagulant Tank Volume[l] | 500 | 500 | 1000 | 1500 | 2000 | 2000 | 3000 | 4000 |

| 81 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Caustic Dosage Pump Capacity[l/h] | 3.5 | 7 | 14 | 24.5 | 35 | 70 | 105 | 140 |

| 82 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Caustic Tank Model- | CDS-200 | CDS-500 | CDS-1000 | CDS-1000 | CDS-1500 | CDS-2000 | CDS-3000 | CDS-4000 |

| 83 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Caustic Tank Volume[l] | 200 | 500 | 1000 | 1000 | 1500 | 2000 | 3000 | 4000 |

| 84 | crisant | 02/10/2024 05:37 AM | crisant | 02/10/2024 05:37 AM | Flocculant (polyelectrolyte) preparation and dosing System Model – | PPS-500 | PPS-1000 | PPS-1500 | PPS-2000 | PPS-3000 | PPS-4000 | PPS-4000 | PPS-5000 |

| MODEL | DAF-5 | DAF-10 | DAF-20 | DAF-35 | DAF-50 | DAF-100 | DAF-150 | DAF-200 |

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | MODEL | DAF 5-L | DAF 10-L | DAF 20-L | DAF 35-L | DAF 50-L | DAF 100-L | DAF 150-L | DAF 200-L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 47 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Annual Hydraulic Capacity [m3/h] | 5 | 10 | 20 | 35 | 50 | 100 | 150 | 200 |

| 48 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Annual Hydraulic Loading Rate[m/h] | 6.7 | 6.7 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| 49 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Free Flotation Area[m2] | 0.45 | 0.9 | 1.6 | 2.8 | 4 | 7.3 | 11.6 | 15.2 |

| 50 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Lamella Surface Area[m2] | 0.3 | 0.6 | 1.2 | 2.1 | 3 | 6.6 | 9.5 | 12.7 |

| 51 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Solid Loading Rate Range[kg/h/m2] | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 | 10.0-30.0 |

| 52 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | A/S – Air-Solid Ratio Range[kg/kg] | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 | 0.01 – 0.06 |

| 53 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flotation Tank Length[mm] | 1200 | 2200 | 3000 | 3000 | 3750 | 5000 | 5500 | 6500 |

| 54 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flotation Tank Height[mm] | 2100 | 2100 | 2100 | 2700 | 2700 | 4000 | 4000 | 4000 |

| 55 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flotation Tank Width[mm] | 1400 | 1400 | 1400 | 1900 | 2400 | 2400 | 3400 | 3400 |

| 56 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Empty Flotation Tank Weight[kg] | 450 | 700 | 950 | 1200 | 1550 | 2300 | 3300 | 4300 |

| 57 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Full Flotation Tank Weight[kg] | 1600 | 2800 | 5200 | 6500 | 9200 | 15000 | 19250 | 25500 |

| 58 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flotation Tank Material- | PP | PP | PP | PP | PP | PP | PP | PP |

| 59 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Skimmer Motor Power[kW] | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 |

| 60 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Recirculation Pump Annual Flow[m3/h] | 0.75 | 1.5 | 3 | 5.25 | 7.5 | 15 | 22.5 | 30 |

| 61 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Recirculation Water Annual Pressure[Bar] | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 | 4.0 -6.0 |

| 62 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Recirculation Pump Motor Power[kW] | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 |

| 63 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Pressurized Tank Volume[l] | 37.5 | 75 | 150 | 262.5 | 375 | 750 | 1125 | 1500 |

| 64 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Annual Pressurized Tank Contact Time[min.] | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 65 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Required Compressed Air Pressure[Bar] | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 |

| 66 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Required Normal Air Flow[Nm3/h] | 7 | 14 | 28 | 49 | 70 | 139 | 208 | 278 |

| 67 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Inlet Connection[DN] | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| 68 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Effluent Connection[DN] | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| 69 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Float Discharge Connection[DN] | 80 | 80 | 80 | 100 | 100 | 125 | 150 | 200 |

| 70 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Settled Solid Discharge Connection[DN] | 50 | 50 | 50 | 65 | 80 | 100 | 125 | 150 |

| 71 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Pressurized Air Connection[inch] | 1/2″ | 1/2″ | 1/2″ | 3/4″ | 3/4″ | 1″ | 1 1/2″ | 2″ |

| 72 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Sludge Screw Power[kW] | N/A | N/A | N/A | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 |

| 73 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Sludge Pump Power[kW] | 0.5 | 0.5 | 0.5 | N/A | N/A | N/A | N/A | N/A |

| 74 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Inline Flocculator Model- | IPF-5 | IPF-10 | IPF-20 | IPF-35 | IPF-50 | IPF-100 | IPF-150 | IPF-200 |

| 75 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Standard Flocculator Tube Material – | U-PVC/PP/PE | |||||||

| 76 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flocculator Tube Diameter [DN] | 63 | 75 | 90 | 110 | 110 | 160 | 200 | 200 |

| 77 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flocculator Total Tube Length [m] | 20 | 30 | 40 | 45 | 62 | 62 | 62 | 80 |

| 78 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Coagulant Dosage Pump Capacity[l/h] | 5 | 10 | 20 | 35 | 50 | 100 | 150 | 200 |

| 79 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Coagulant Tank Model- | CDS-500 | CDS-500 | CDS-1000 | CDS-1000 | CDS-2000 | CDS-2000 | CDS-3000 | CDS-4000 |

| 80 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Coagulant Tank Volume[l] | 500 | 500 | 1000 | 1500 | 2000 | 2000 | 3000 | 4000 |

| 81 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Caustic Dosage Pump Capacity[l/h] | 3.5 | 7 | 14 | 24.5 | 35 | 70 | 105 | 140 |

| 82 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Caustic Tank Model- | CDS-200 | CDS-500 | CDS-1000 | CDS-1000 | CDS-1500 | CDS-2000 | CDS-3000 | CDS-4000 |

| 83 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Caustic Tank Volume[l] | 200 | 500 | 1000 | 1000 | 1500 | 2000 | 3000 | 4000 |

| 84 | crisant | 02/10/2024 05:45 AM | crisant | 02/10/2024 05:45 AM | Flocculant (polyelectrolyte) preparation and dosing System Model – | PPS-500 | PPS-1000 | PPS-1500 | PPS-2000 | PPS-3000 | PPS-4000 | PPS-4000 | PPS-5000 |

| MODEL | DAF 5-L | DAF 10-L | DAF 20-L | DAF 35-L | DAF 50-L | DAF 100-L | DAF 150-L | DAF 200-L |

*MAT-KULING AS™ preserves the right to update anytime the listed prices (if any). Every effort has been made so that the above specs are accurate. However please contact our Sales Department for up to date technical data, electrical specs according to your regional requirements and current Ex-Works pricelist. The listed prices are for the basic equipment and do not include any optional components.